Many people have noticed the small circular dent on the side of a plastic milk jug, yet few pause to consider why it exists. At first glance, it seems like a minor design detail—perhaps decorative or simply part of the molding process. In reality, that circular indentation is a deliberate engineering feature with several practical purposes. Plastic milk jugs are designed to be lightweight, affordable, and durable, all while safely holding a perishable liquid that moves through a complex supply chain. From the dairy processing plant to refrigerated trucks, grocery store shelves, and finally home refrigerators, milk containers endure constant handling and temperature fluctuations. The circular dent plays an important role in helping the jug withstand these everyday stresses. Manufacturers carefully incorporate this feature to improve safety, flexibility, and structural strength without increasing material costs. What looks like a simple dimple is actually a smart solution to multiple packaging challenges.

One of the primary functions of the circular dent is pressure regulation. Liquids expand when warmed and contract when cooled, and milk is no exception. During transportation, jugs may experience temperature shifts as they move between cold storage facilities and loading docks. Even small changes in temperature can create internal pressure differences inside a sealed container. Without a flexible design element, that pressure could strain the plastic walls, increasing the risk of cracks, leaks, or even bursting. The circular indentation acts as a built-in expansion panel. When pressure inside the jug rises, the dent can flex outward slightly, absorbing the stress. When temperatures drop and pressure decreases, it can flex inward. This ability to move subtly helps protect the structural integrity of the jug. Instead of fighting against the laws of physics, the design works with them, allowing the container to adapt naturally to environmental changes.

Beyond pressure control, the circular dent also strengthens the jug through geometry. Rounded shapes are inherently strong because they distribute force more evenly than flat surfaces. Engineers use curves and arcs in architecture and product design for this very reason. The circular indentation reinforces the sidewall of the jug, helping it resist deformation when squeezed, stacked, or bumped. Rather than relying on thicker plastic—which would increase costs and material use—manufacturers can maintain a lightweight design while still achieving durability. This is particularly important during shipping and stocking. Milk jugs are often packed tightly in crates or cartons, and they may shift during transit. The dent adds rigidity without sacrificing flexibility, striking a balance between strength and efficiency. In large-scale production, even small design optimizations can lead to significant savings in materials and environmental impact.

The dent also contributes to impact resistance during everyday handling. At home, milk jugs are frequently lifted, tilted, squeezed, and occasionally dropped. When someone grips the container firmly, the pressure applied to the sides could potentially weaken flat plastic surfaces over time. The circular indentation helps disperse that force, reducing stress concentration in any one area. If the jug is knocked against a refrigerator shelf or counter, the curved design helps absorb some of the shock. This reduces the likelihood of cracks forming at weak points. In this way, the dent serves as a protective buffer. It may seem insignificant, but without it, the container would be more vulnerable to everyday wear and tear. The feature enhances reliability, ensuring that milk stays securely contained from purchase to final pour.

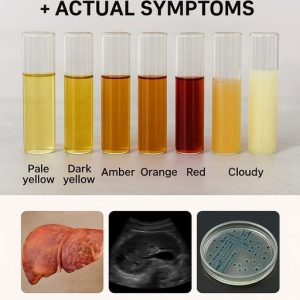

Another subtle advantage of the circular dent is its visual feedback. Sometimes consumers notice that the dent appears slightly pushed outward or inward. This can happen due to normal pressure shifts inside the jug. If the milk has warmed slightly, the dent may bulge outward; if it has cooled, it may pull inward. In some cases, a significant outward bulge could indicate spoilage, as gases produced by bacterial growth increase internal pressure. While the dent itself is not a precise freshness indicator, its movement can provide a visual cue that something inside the container has changed. This flexibility is intentional. The design allows for movement without compromising the seal. Instead of cracking under pressure, the jug flexes. That adaptability contributes to both safety and practicality in everyday use.

The circular dent works alongside other structural features of the milk jug, such as the handle cutout, ribbed base, and reinforced neck. Each element is carefully engineered to optimize performance while minimizing material usage. The handle distributes weight for easier pouring, the base ridges add stability, and the neck supports the cap and seal. Together, these components create a container that is lightweight yet strong enough to protect a fragile product. The dent is part of this integrated system. It reflects the thoughtful engineering behind even the most ordinary household items. Though it may appear simple, it represents a balance of physics, material science, cost efficiency, and consumer convenience. The next time you pick up a milk jug, that small circular indentation serves as a quiet reminder that everyday objects often contain clever design solutions hidden in plain sight.